Ethyllene Oxide Sterilization Basics

Origianaly used for the sterilization of spices and leafy herbs, Ethylene oxide (EO) eventually made it's way to the sterilization o medical devices. this movw was prompted by the arrival o plastics and disposables to the device ield. The relativaly low process temprature (in compration to steam sterilization) has made Ethylene Oxide Sterilization an excellent method for many products.

The Process:

Unlike other method of sterilization, such as gamma, EO sterilization Process may be lengthy. Products are preconditioned prior to EO Exposure. This precondition may ocuur in sterilization chamner itself, or in a temprature and humidity settings determind during the sterilization Validation. After a set time the product is removed and placed into the sterilization chamber.

The Properties that make Eo Such good methylating agent also makes it extremly dangerous at ambient oxygen levels. To ensure an intrinsically safe enviroment for the Eo Set of evecuations coupled with steam additions excuted. Adding nitrogen to chamber is another way to reduce th edanger as well as allowing EO to sit with the products at close to ambient pressures.

Eo gas is then added and allowed to sit with the product. histrocaly the amount o Gas added was set to perticular weight. however the evolution of the process has gradually gone to adding gas to a validated pressure(concentration o gas).

during this "Sitting Phase" or "EO Gas Dwall Phase" the products abosrbs EO gas. to maintain the gas concentraion and offset the absorpation - additional gas is added.

Following the Gas Dwell phase a series of evecution and air imbleeds ocuur. This helps in the removal of the gas from the products. the products is then transered to an aeration Chamber or ROOm where EO (and Eo degradation products) dissipates safely fron the products. Depending on the nature of the products/packaging and aeration conditions theis gas dissipation period may last from several hours to weeks (and even moths).

APPLICATIONS OF ETHYLENE OXIDE STERILIZERS

- In hydration plants where (onion powder, onion flakes, garlic powder, garlic flakes.

- Products are manufactured and exported.

- In plywood industries where ply woods are sterilized against white ants and residual bacteria.

- In food industries where various seeds like sesame seeds are sterilized and exported. Wheat flour, grains, all types of spices etc.

- In pharmaceutical products, hospitals, Used in industries where all the food products are exported.

- IV Sets, IV Catheters, cannula, Syringes, Urine bags, blood bags.

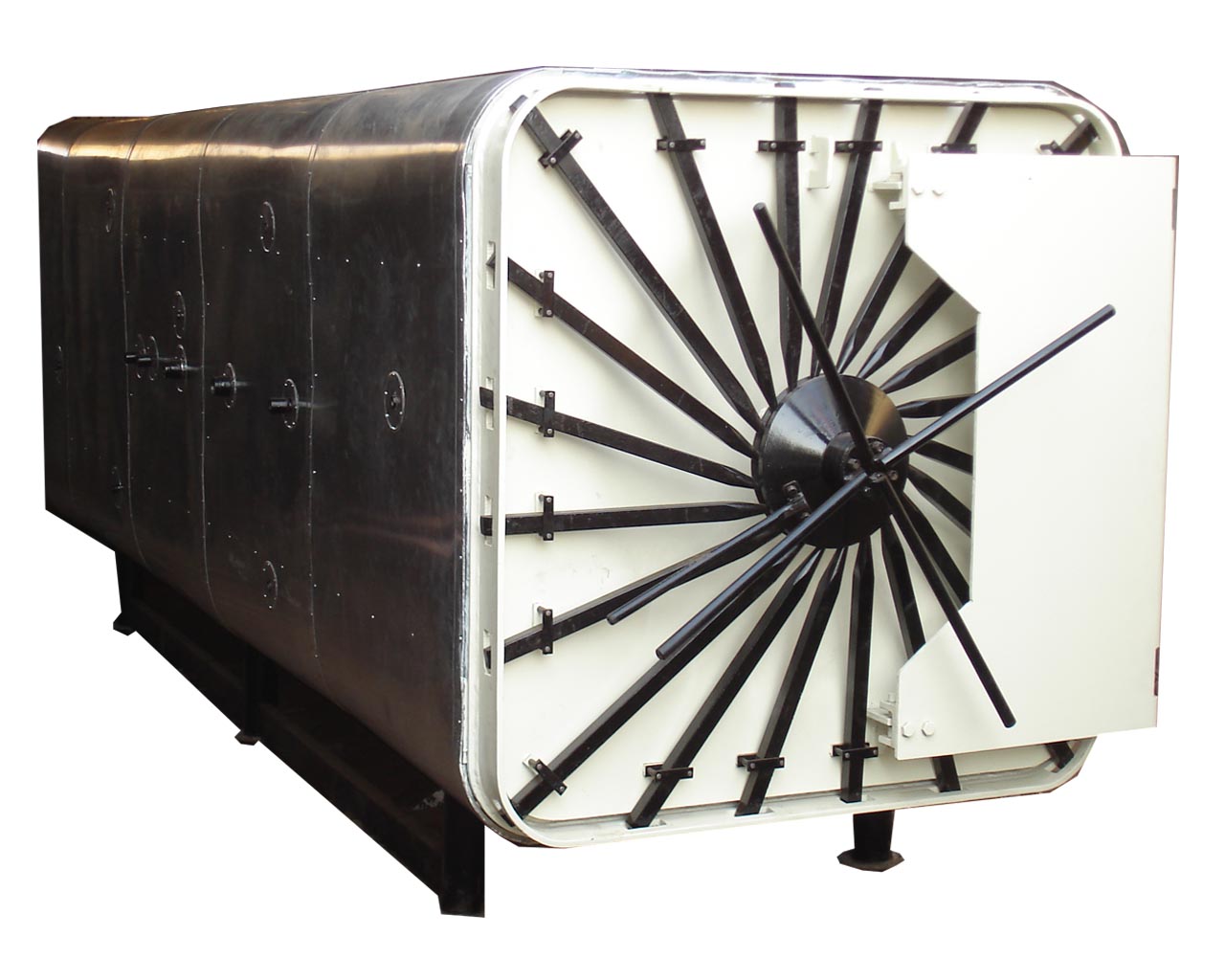

ETO Sterilizer : We are manufacturers & Exporter of ETO Sterilization, Ethylene Oxide Sterilizers, ETO Sterilzation Equipment, Pharmaceutical ETO Sterilizers, Medical Sterilizers Suppliers, ETO Sterilizers, ETO Sterilizer, Stem Sterilizer, E.T.O. Sterilizer and E.T.O. Sterilization in Ahmedabad, Gujarat, Delhi, Mumbai, Hyderabad, Rajkot, Kolkata, Pune, India.

Products

- Industrial Tray Dryer

- Chemical Machinery & Equipment

- Pharmaceutical Equipment

- Paint Machinery

- Resin Manufacturing Plant & Machinery

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Drum Flaker

- Attritor

- Twin Shaft Disperser

- Triple Roll Mill / Three Roll Mill

- Pvc Solvent Cement Adhesive Machine

- Pharmaceutical Octagonal Blender

- Pharmaceutical Ribbon Blender

- Reaction Vessel Exporter in India

- sigma mixer manufacturer