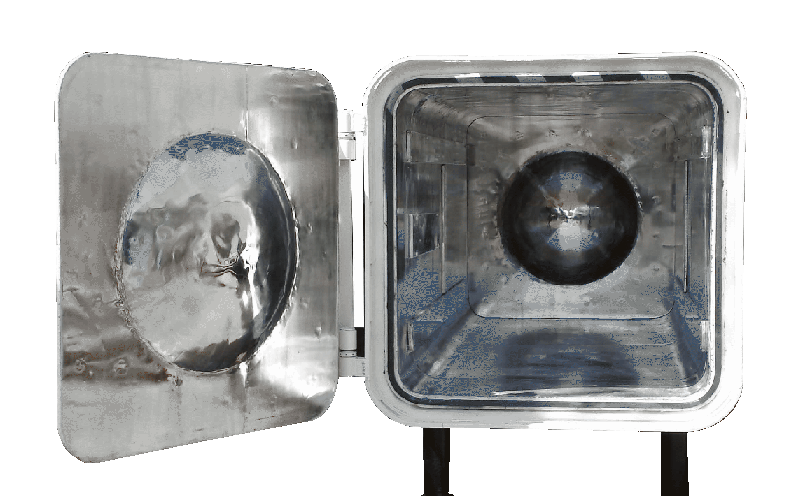

ETO Sterilizer Machine

Ethylene oxide sterilization is a chemical process consisting of four primary variables: gas concentration, humidity, temperature and time. Ethylene oxide is an agent that disrupts the DNA of microorganisms, which prevents them from reproducing. EO sterilization assures that a safe and sterile product will be delivered to the market each and every time.

Ethylene oxide sterilization is a chemical process consisting of four primary variables: gas concentration, humidity, temperature and time. Ethylene oxide is an agent that disrupts the DNA of microorganisms, which prevents them from reproducing. EO sterilization assures that a safe and sterile product will be delivered to the market each and every time.

ETO Sterilizer Features

- ALL INDUSTRIAL ETO STERILIZERS ARE DESIGNED AND BUILT AS PER CUSTOMER’S REQUREMENTS TAKING INTO CONSIDERATION THE FOLLOWING VARIABLES;

- To Sterilize Surgical Medical Device roducts like I.V. Sets, Disposable Syringes, Disposable Surgical Set, catheter, Urin Bag, reduce microbiological load; and increase life span of material.

- Modular construction of chamber.

- Model is available from 1/2 CU.MTR TO 20 CU.MTR.

- Easy to operate.

- Fully automatic operation based on PLC control (optional).

- Semi Automatic (Pneumatically Operated Ball Valave) Control

- Better productivity & lesser mixing time.

- Contact parts are SS 304 / 316.

- Process time about 8 hrs.

- IQ/OQ/DQ documentation(OPTIONAL).

- It is useful for prevention of micro biological contamination retairing flavour useful for treatment of spices, dried nuts, Foods Packed cereals etc.

Products

- Industrial Tray Dryer

- Chemical Machinery & Equipment

- Pharmaceutical Equipment

- Paint Machinery

- Resin Manufacturing Plant & Machinery

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Drum Flaker

- Attritor

- Twin Shaft Disperser

- Triple Roll Mill / Three Roll Mill

- Pvc Solvent Cement Adhesive Machine

- Pharmaceutical Octagonal Blender

- Pharmaceutical Ribbon Blender

- Reaction Vessel Exporter in India

- sigma mixer manufacturer